Gravity feed spray guns are a type of spray painting equipment that uses gravity to supply paint to the nozzle. They are popular choice for many DIYers, hobbyists, and professional painters alike due to their ease of use, and ability to achieve smooth, high-quality finishes.

In a gravity feed spray gun, the paint cup is located on top of the gun, above the nozzle. Paint flows down into the nozzle via gravity. With gravity pulling the paint down into the spray pattern, you get an even distribution of paint coming out of the nozzle. This allows for a more uniform coat of paint or clear coat to be applied. It also reduces the risk of paint thinning and sputtering.

Gravity feed guns also require less thinning of the paint or coating material. Because gravity pulls the paint down into the air stream, the paint doesn't need to be thinned as much to spray evenly. This saves on materials and allows the paint to retain more of its original viscosity and spray characteristics.

Gravity feeding enables spray guns to function at lower air pressures. Lower pressure equals better control for the user, allowing them to achieve smoother, higher quality finishes. The reduced overspray also leads to increased transfer efficiency, meaning less wasted paint. Gravity feed is therefore the preferred method for precision work requiring fine atomization at low psi settings.

The top-mounted cup provides nice visibility as you spray, allowing you to see exactly where the paint is going. Cleaning a gravity feed spray gun is also much simpler. With the paint cup on top, quick access is available to the crucial areas that need paint cleaned out like the nozzle, fluid tip and air cap.

There are some downsides to gravity feed spray guns to consider as well. The biggest disadvantage is their limited paint cup capacity. Because the cup sits on top of the gun, it can only hold a limited amount of paint, usually around 600cc depending on the model. This requires more frequent filling for bigger jobs.

So when should you choose a gravity feed spray gun?

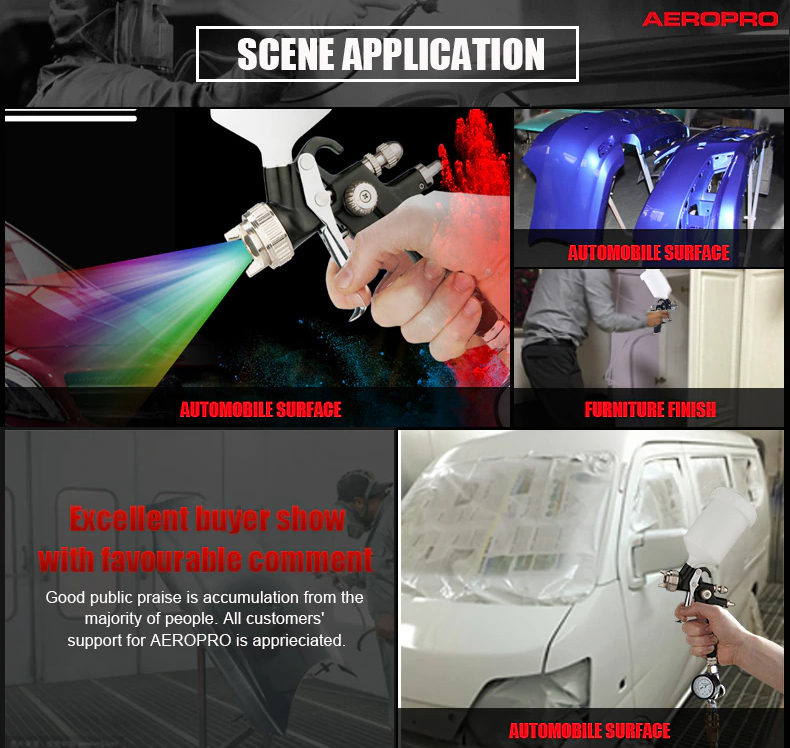

Gravity feed guns are the number one choice for auto body painting. Their fine finish capabilities allow painters to achieve the smooth coats needed for that automotive finish. The ability to spray at low pressures gives painters more control over the spray fan, enabling them to easily spray hard to reach areas and vertical surfaces. The reduced overspray also means less time spent masking off areas you don't want painted.

For painters and woodworkers applying stains, sealers, lacquers and varnishes, the control of a gravity spray gun is essential. The ability to spray thin materials at low pressures makes gravity feed an ideal choice for applying fine finishes to furniture, cabinetry, doors, chairs, tables, and other woodworking projects.

For small items, touch-ups, and detail work, a gravity feed gun offers precision. The lower psi lets users control the spray to apply only the desired amount of paint exactly where they want it. This makes correcting flaws and painting small areas much simpler.

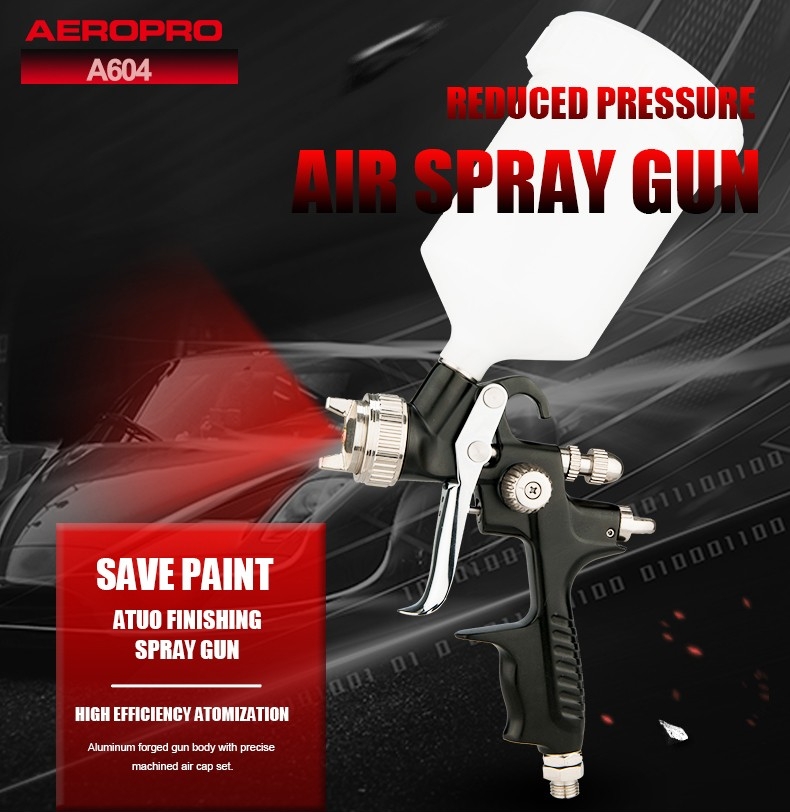

Gravity feed guns are commonly used with HVLP systems, AEROPRO A604 HVLP spray gun provides optimal paint delivery for superb atomization at lower air cap pressures. This feature-packed spray gun comes with Stainless steel needle and nozzle , for handling variety of paints with ease.

Model | Type of Feed | Standard Nozzle | Operating Pressure | Pattern Width | Air Consumption | Paint Capacity |

A604 | Gravity | Φ1.3mm | 2.0bar | 180-260mm | 4.1-4.5cfm | 500c |

View more about AEROPRO HVLP spray guns.

If you need product quotation service, please contact: sales@aeroprotools.com