Achieving a smooth, professional looking base coat on your automotive paint job starts with using the right spray gun. If you want a base coat with a factory quality finish, an HVLP spray gun needs to be your go-to paint application tool.

Understand Base Coat Difference

Base coat paint has a very different composition compared to single stage paints. It is formulated to be applied in thin, even coats, allowing the metallic flakes or pearls to lay flat for maximum effect. Applying too heavy of a coat can obscure this effect and create issues like solvent popping or loss of adhesion. Base coats are also more prone to runs and sags compared to single stage paint.

The base coat provides color and coverage. It goes directly on the prepared bare metal or sanded primer surface. Multiple coats of base may be applied to achieve the desired coverage and hue. The base coat layers are then sealed with clear coat, which provides gloss, depth and protection from the elements. HVLP guns excel at laying down even coats of base paint.

Prepare Your Paint Properly

Mixing and thinning the base coat properly is critical for good sprayability. Always mix the paint thoroughly to suspend the metallic flakes evenly throughout the paint. A typical starting point is 1:1 paint to thinner for easy atomization. Make small adjustments as needed for your local conditions. Strain the paint into your paint cup through a fine mesh funnel or paint strainer to catch any particles that could clog the spray gun.

Set Up Your HVLP Spray Gun

There are a few key settings to dial in for optimal base coat application. First, use the largest nozzle and air cap on your HVLP suitable for automotive paint. This will produce a softer spray pattern ideal for metallic base. Set the fluid knob to approximately 1/2 to 3/4 open. Finally, adjust the air pressure. Most HVLP guns operate best around 6-10 PSI at the cap for base coat. Test your pattern on cardboard first. You want enough pressure for good atomization but too much will create dry spray.

Prep Your Surface Properly

Apply base coat only over properly prepped and sealed substrates. The surface should be free of flaws, debris and be uniformly sanded. Make any final repairs and block sand the primer until satisfaction. Clean the surface thoroughly and apply a sealer primer designed for base coat. Allow proper flash times between coats. The surface should be as smooth as possible before spraying your base.

Spray Technique Matters

Keep the distance constant as you spray in straight, even parallel paths. Move the gun either vertically or horizontally, not in an arc. Avoid letting the gun sway back and forth. Gently pull the trigger to avoid splatter. Release at the end of each pass. Overlap each stroke about 30%. This helps avoid striping and missed spots.

Move at a moderate pace, too fast can cause dry spray while too slow increases the chance of runs. Hold the trigger down at the beginning and end of each pass to get good edge coverage. Spray the borders first then fill in the middle. If you see runs or drips forming, wait longer between coats.

The key to flawless base coat is several light, even coats. Heavier coats will not improve the appearance or speed the process. Allow proper flash time between coats - usually 5-10 minutes in 70F temperatures. Check for full coverage and reapply additional coats as needed until the base has built up with a uniform look. 2-4 coats are typical for full coverage. Don't be tempted to keep applying coats unnecessarily. Too many coats can move around metallic flakes.

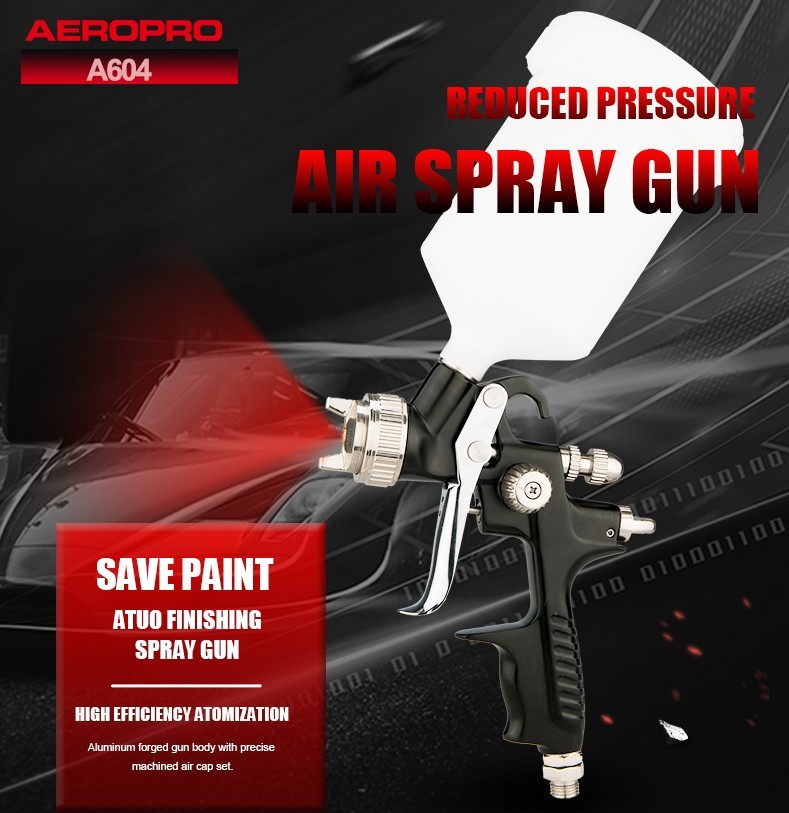

AEROPRO A604 Top Grade HVLP spray guns are designed to atomize paint at lower air pressures, allowing for maximum transfer efficiency and reducing overspray. This makes them ideal for applying delicate base coat paints.

AEROPRO A604 with adjustable settings allows precise control of paint flow, pattern, and air pressure. The desired pattern, volume of fluid output and fine atomization can easily be obtained by regulating the Pattern Adjusting Knob, Fluid Adjusting Knob and Air Adjusting Knob.

Aluminum forged gun body with precise machined air cap set. Stainless steel needle and nozzle accommodate a variety of coating. Even better surface quality for spotless finish. Ensure excellent painting results. Great for Automobile finish painting. Suitable for professional painters, maintainer, DIYers, auto hobbyists.

Model No:A604

Feed Type: Gravity

Standard of Nozzle: Φ1.3mm

Operating Pressure: 2.0bar

Pattern Width: 180-260mm

Paint Capacity: 500cc

Air Consumption: 4.1~4.5cfm,117-128L/Min

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com