HVLP systems provide an incredibly fine atomized spray pattern, superior transfer efficiency, and excellent finish quality - making them ideal for everything from automotive refinishing to woodworking and more.

Proper Thinning Ratios Are Critical

One unique characteristic of HVLP systems is their sheer fluid-moving capabilities enabled by the lower pressure design. This means they can handle higher viscosity coating materials that would quickly clog the smaller components of traditional spray guns.

However, don't make the mistake of assuming you can simply pour straight from the can. Coatings still need to be thinned to the ideal viscosity per the spray gun, typically measured on a viscosity cup in seconds rather than strictly by volume ratios. Get the ratios right for your specific coating and you'll experience that gently atomized HVLP spray pattern.

Adjusting Air Pressure & Fluid Flow

For proper HVLP operation, the air pressure needs to stay within a specific range - usually somewhere between 10-20 PSI at the air cap.

With the air hose connected, trigger the spray gun and use the pressure regulator on the turbine/compressor to adjust the dynamic air pressure as measured right at the air cap. Get it too high, and you lose the HVLP efficiency; too low and the atomization suffers.

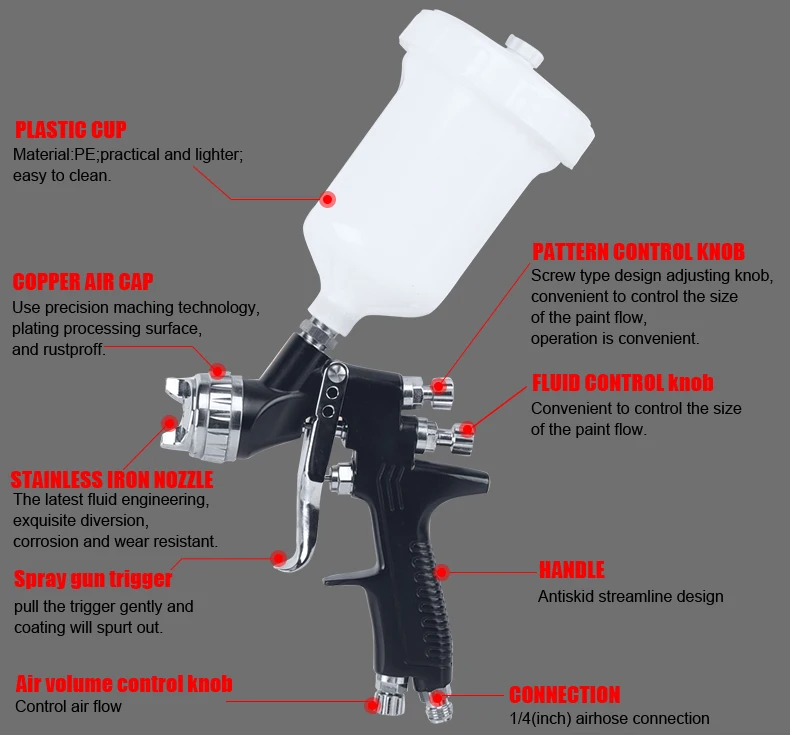

The fluid flow refers to how much paint the spray gun releases, which impacts the mil-thickness of each pass. Adjust the fluid knob at the rear of the spray gun body to dial in the desired fluid flow rate. Start around halfway open, test on a sample, then increase or decrease as needed.

Don't Forget the Air Cap

Checking, cleaning, and potentially replacing your HVLP air cap, the small component at the end of the gun that shapes and focuses the pattern of atomized paint particles.

If your paint pattern starts exhibiting streaky tails or rounded bulges on the edges, that's likely a sign of built-up dried paint or damage in those minuscule air holes around the nozzle. Make it routine to soak and deep clean the air cap with every color change at minimum. A clean or fresh air cap ensures your ability to lay down that beautiful, precisely controlled HVLP pattern every time.

Dial In Your Gun Motions

While techniques vary across painting applications, a core HVLP best practice is maintaining a consistent 6-10 inch distance from the surface, moving parallel with a 50% overlap between each pass. Avoid arcing motions, as they can lead to uneven coverage and potential drips or runs.

Practicing that steady, parallel motion on a scrap piece, perfecting your trigger pull technique to avoid sputtering at the start/end of each pass. Attempting to get too close, waving the gun, or fanning the pattern will disrupt the laminar airflow and coating pattern. Trust the HVLP air stream to evenly distribute the coating at that prescribed distance.

Backroll for Consistent Coverage

While HVLP excels at achieving that elusive even coverage, another pro-tip is to backroll immediately behind your spray pattern with a high-density foam roller. The backrolling motion helps press the coating into any lingering high/low spots for a silky-smooth finish, while also enabling more consistent film builds.

Learning this technique will improve your HVLP skills and producing factory-quality finishes, even in tight spaces or vertical surface applications. But be careful not to overwork the area, which can create excess bubbling.

Designed with the user in mind, the AEROPRO A605 is a high-volume, low-pressure (HVLP) spray gun that delivers exceptional efficiency.

Aluminum alloy gun body with anodic treatment surface. Air micrometer with graduations to adjust atomization air. It features a premium stainless steel fluid nozzle and precision machined air cap to ensure a uniform fan pattern. Combined with lower fluid pressure, this allows for better control, free of thick areas or dry spots.

Spray gun body designed with small dimensions and low weight for fatigue-free working. Single-handed flat control to adjust the spray pattern to the object which is to be painted.

Best used for vehicles, furniture, instrumentation, mechanical equipment, spraying operation, suitable for water soluble paint spraying.

Model No:A605

Standard Nozzle:φ1.3mm

Operating Pressure:2.4-3.0bar

Pattern Width:200-300mm

Air Consumption:5.5cfm

Paint Capacity:400cc

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com