Most people are familiar with standard power drills that plug into an electrical outlet. But there's another type of drill that doesn't get as much attention - the pneumatic drill. Powered by compressed air, these powerful tools have a wide range of applications across many industries.

At the core of every pneumatic drill lies a meticulously engineered mechanism that harnesses the power of compressed air to generate rotational force. This force is then transferred to the drill bit, allowing it to pierce through even the tough materials with remarkable ease.

The robust casing of a pneumatic drill not only protects the internal components but also serves as a heat sink, dissipating the heat generated during operation and ensuring consistent performance even under continuous use.

Another major benefit is their simplicity and durability. With minimal moving parts and no electrical components, pneumatic drills are extremely hardy tools built to withstand rough job site conditions, vibrations, dust, and moisture that could easily damage an electric drill. Their ruggedness and low maintenance requirements make pneumatic drills a favorite choice for construction, mining, and industrial applications.

Pneumatic Drill Accessories and Attachments

To further enhance the versatility and functionality of pneumatic drills, there have a wide range of accessories and attachments.

Drill Chucks: Available in various sizes and types (keyed, keyless, etc.), drill chucks securely hold the drill bits in place, allowing for quick and easy bit changes.

Drill Bits: Pneumatic drills can accommodate a variety of drill bit types, including twist bits, step bits, and hole saws, depending on the material and application.

Angle Attachments: These attachments allow the drill to operate at different angles, providing access to hard-to-reach areas or enabling drilling in specific orientations.

Depth Stops: Also known as depth gauges, these accessories help control the depth of the drilled hole, ensuring precision and consistency in drilling operations.

Air Filters and Regulators: To ensure optimal performance and longevity, pneumatic drills require clean, regulated air supply. Air filters and regulators help achieve this by removing contaminants and maintaining consistent air pressure.

Applications and Versatility

Pneumatic drills excel in a wide range of applications, each demanding a unique combination of power, precision, and durability. From heavy-duty construction sites to precision engineering workshops, these versatile tools have become indispensable workhorses.

Construction and Demolition: In the construction and demolition industries, pneumatic drills are invaluable tools for drilling through concrete, masonry, and other tough materials. Their high torque and impact force make them ideal for tasks such as anchor bolt installations, core drilling, and even demolition work involving breaking through concrete structures.

Manufacturing and Metalworking: In manufacturing and metalworking environments, pneumatic drills shine when it comes to drilling through thick metal plates, structural steel, and other high-strength materials. Their ability to maintain consistent power and torque, even under demanding conditions, ensures precise and efficient drilling operations.

Automotive and Repair: In the automotive and repair sectors, pneumatic drills are indispensable for tasks such as drilling through engine blocks, chassis components, and other heavy-duty applications. Their compact design and ease of maneuverability make them well-suited for working in tight spaces, while their power ensures efficient material removal.

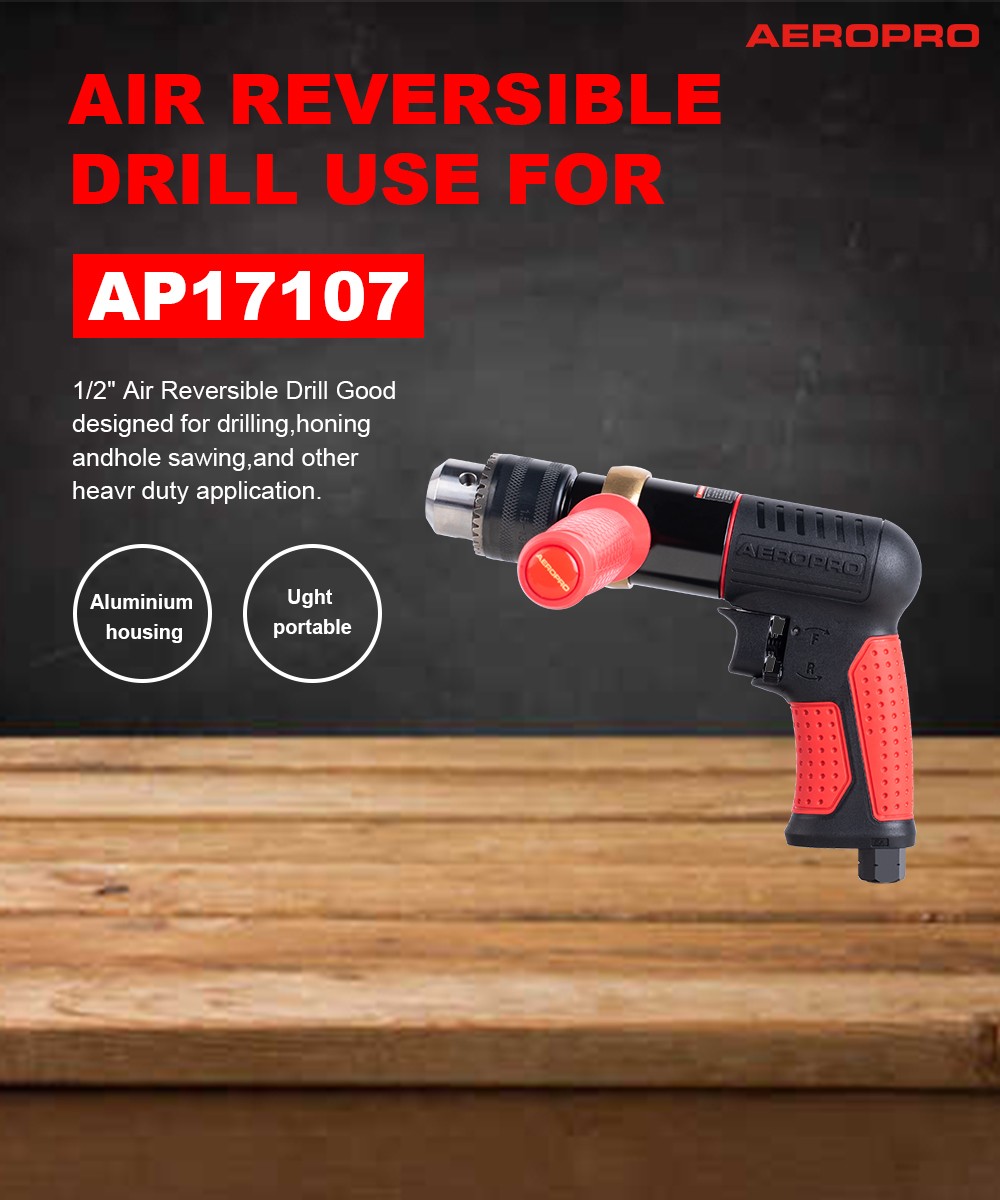

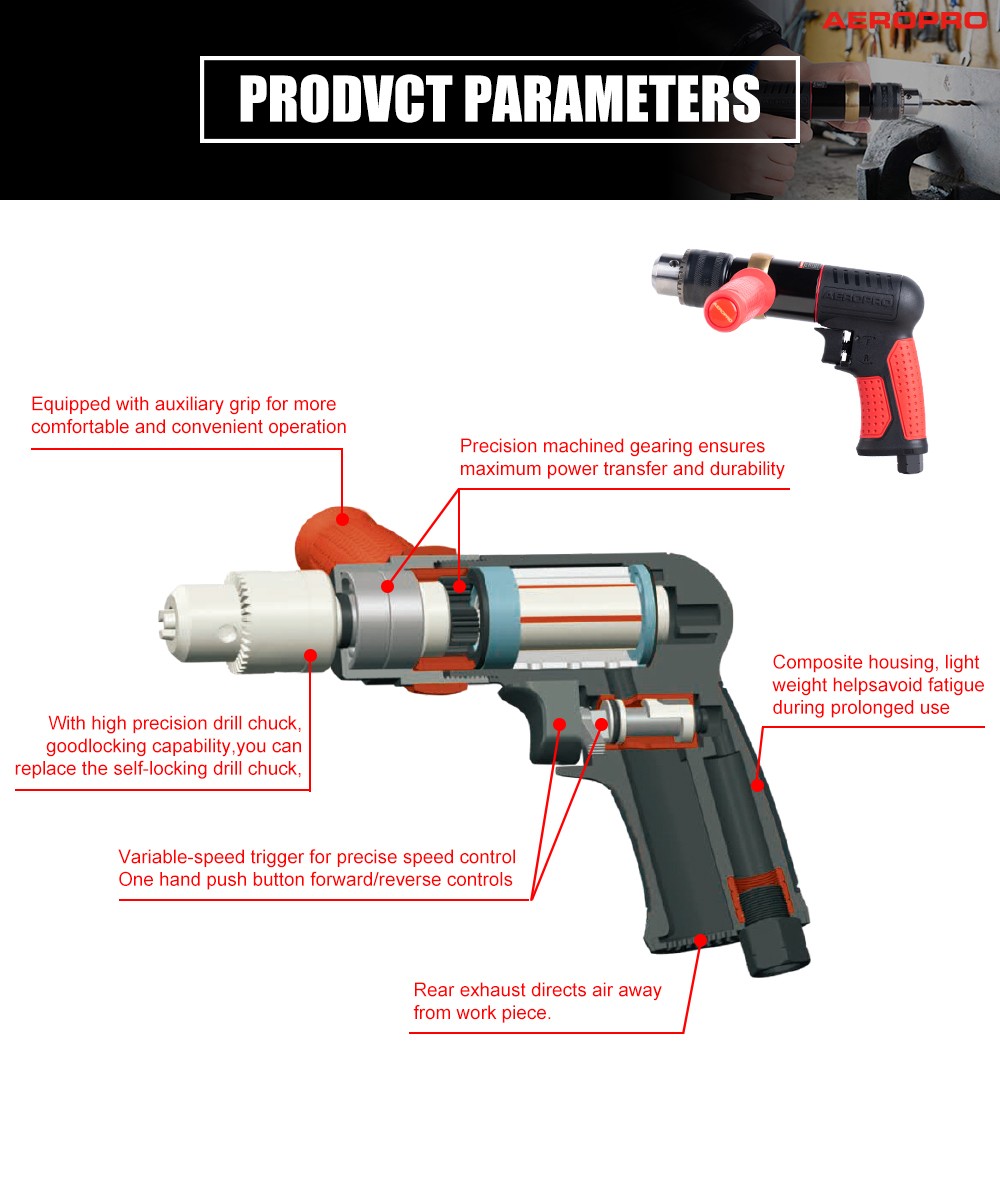

Designed for professional use, the AEROPRO AP17107 reversible pneumatic drill is built tough to withstand years of heavy use. High precision chuck. Bakelite rotor blade. P6 industrial bearing,long working life. Composite with glass fiber body, light weight and not easy to be deformed in low or high temperature. Rotor have be heat treated by Ipsen which import from Germany.

Composite housing, light weight helps avoid fatigue during prolonged use. Variable speed throttle for easy starts. Precision machined gearing ensures maximum power transfer and durability. Rear exhaust directs air away from work piece. Variable-speed trigger for precise speed control. One hand push button forward/reverse controls.

Ideal for home improvement projects, body work installation and repair, farm implement assembly and repair, construction, metal or wood fabrication, general equipment, and auto repair and maintenance.

Model No:AP17107

Free Speed:700Rpm

Air Inlet (Npt):1/4"

Air Hose(Id):3/8"

Avg.Air Consumption:4cfm(114L/min)

Sug.Air Comp:2Hp

Net Weight:1.4kg

Overall Length:195mm

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com