Doing proper touch ups and blending on automotive paint jobs requires much more than just having the spray gun equipment. Many amateur auto body painters think they can just pick up a cheap gun, give it a few pumps, and get spraying. But achieving a professional-looking paint job requires much more nuance.

For touch up spray guns using compressed air, the sweet spot is usually between 15-30 PSI. This allows enough force to vaporize the paint into microscopic droplets without being too intense. The exact pressure will depend on the viscosity of the paint, length of hose, and a few other variables.

My suggestion is to start around 15 PSI and do some test sprays on plastic sheeting. If you see spitting or finger painting effects, increase pressure incrementally up to 25 PSI. If it's blowing out in an dusty mist before it hits the surface, try dialing it down in 2-3 PSI increments. Getting that air pressure just right takes a bit of trial and error. But once dialed in, you'll see the difference in how smoothly and evenly the paint lays down.

Regulating Fluid Flow

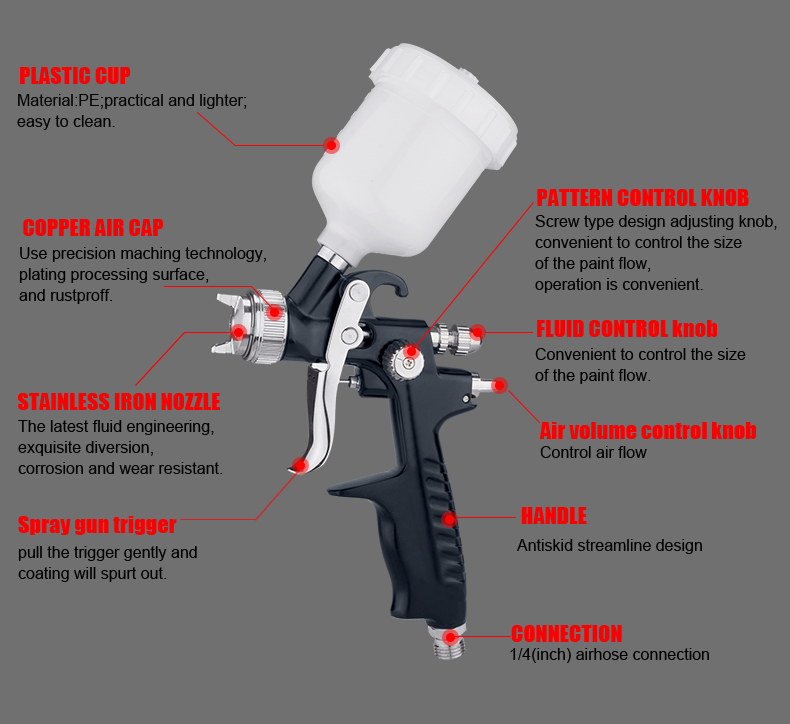

With air pressure set for proper atomization, the next step is controlling the fluid flow of paint through the nozzle to match the pump's output capacity. This prevents common issues like spitting, streaking, and build up around the air cap.

Most mid-range to professional grade touch up spray guns will have a fluid knob or screw to adjust the paint flow rate. Start with the knob wide open and do some spray tests on a vertical surface. You want to see that perfect mist with no heavy areas or dry spots in the spray pattern.

If there are dry spots in the middle, increase paint flow slightly. If it's too wet or forming drips, reduce fluid flow incrementally. Keep making adjustments until you have a consistent, even distribution of atomized paint across the entire spray pattern.

Fan Pattern Adjustments

For blending paint seamlessly during touch ups, having the right fan pattern width and distribution is essential. Generally for spot repairs, you want an angled/oval fan pattern about 4-6 inches wide where the paint is slightly more concentrated and wet in the center. This allows you to lay down more paint where you need it.

To expand the fan width for broader coverage, keep opening the air cap or turning the fan adjustment knob until you reach the desired pattern size. For tighter touch ups, slowly close down the air cap until the fan narrows to a smaller oval. The key is atomizing enough paint while still maintaining that concentrated center for clean overlapping passes and smooth blending into the existing paint job.

Masking and Blending Technique

If the touched up section will blend into the existing paint, proper masking is a must to prevent any hard lines or stark color breaks. Use high quality automotive masking tape and paper to mask off the blend areas.

When spraying, extend your painting passes out into the masked area, overlapping slightly each time to carefully blend and diffuse the new paint into the old. This requires a very delicate tough and skillful control of the spray gun. Remove the masking tape carefully before the paint fully cures using an angle to prevent paint cracking or chipping along the edge. The blended area should be virtually undetectable when done correctly.

The AEROPRO A606 Touch Up Auto Refinishing Spray Gun designed for the professional who demands delicate finishes. The A606's adjustable fan control enables painters to easily dial in the perfect fan pattern for repair area.

Spray gun body designed with small dimensions and low weight for fatigue-free working. Air micrometer with graduations to adjust atomization air. Aluminum alloy gun body with anodic treatment surface. Stainless steel needle and nozzle accommodate a variety of coating.

Even better surface quality for spotless finish. Best used for car spray painting of middle or high adhesive for surface finishing and middle coating.

Model No:A606

Feed Type: Gravity

Standard of Nozzle: Φ1.0mm

Operating Pressure: 2.0bar

Pattern Width: 130mm

Paint Capacity: 100cc

Air Consumption: 2.8-.4.6cfm(79.6-130L/Min)

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com