Not only delivers immense power, but does so in a compact and lightweight package compared to electric drills of similar capabilities. Pneumatic technology offers more than just brawn.

How Air Drills Work

Air Inlet. This is where the compressed air hose attaches to feed air into the drill.

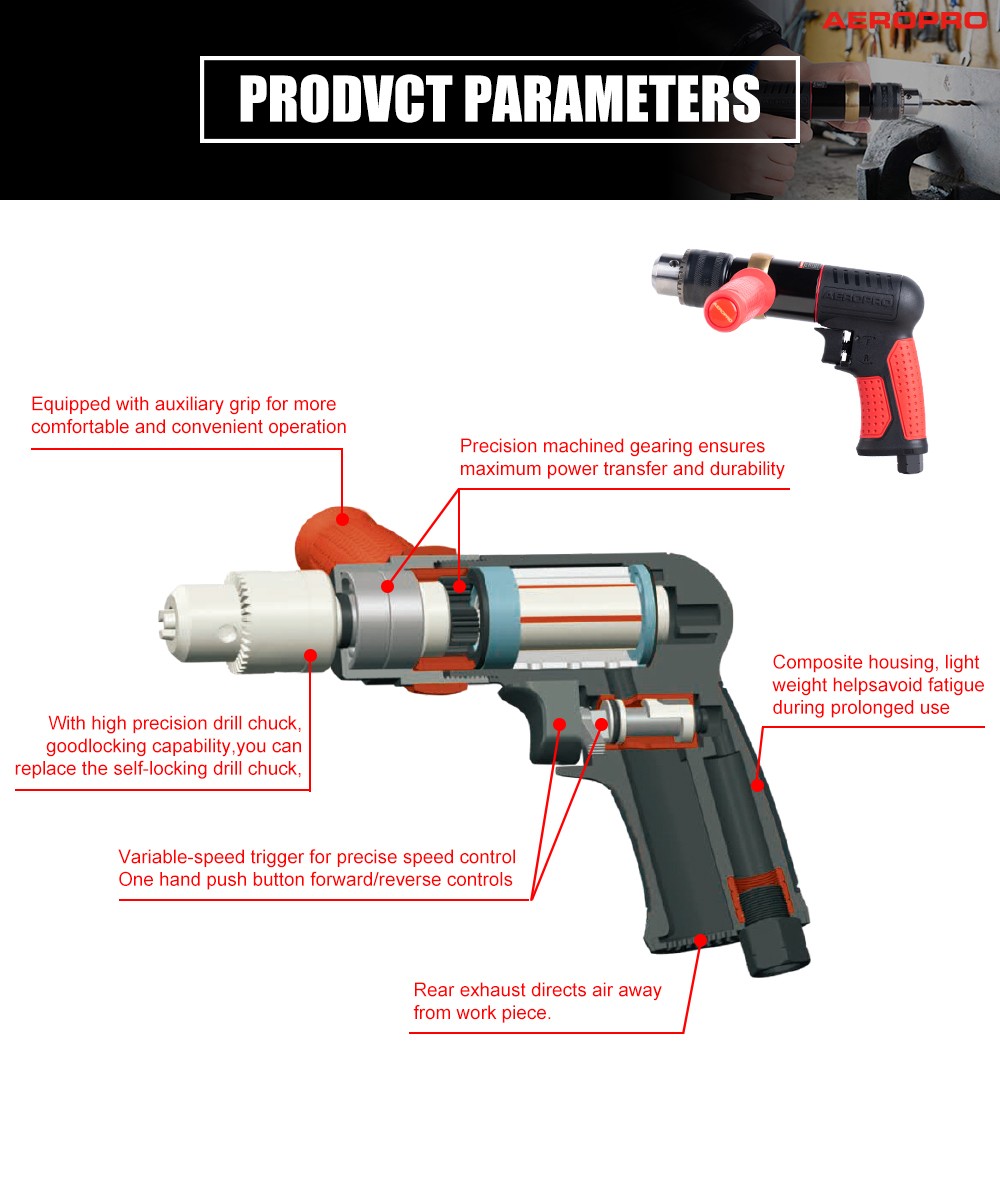

Reverse Valve. A mechanical valve that allows you to switch between forward and reverse rotation. Throttle Valve. The trigger controlled valve that meters airflow and controls the drill speed. Rotor/Vane Assembly. The rotational mechanism that spins using the air flow, driving the drill chuck. Bearings. Allows smooth, low-friction rotation of the internal components. Drill Chuck. The three-jaw clamp that securely holds the drill bit in place. Motor Housing. The body that encases and protects all of the internal components.

Air motors are incredibly simple with far fewer moving parts, making them lighter, easier to maintain, and almost impervious to dust and debris. More importantly, they can deliver huge amounts of rotational torque and power while remaining relatively compact.

Simple Maintenance

Since the air motor has just a handful of moving parts surrounded by grease, it's essentially self-lubricating for the life of the tool. The lack of brushes or internal electrical components prevents a common failure point.

About the only user maintenance is to periodically disassemble the drill, clean out any grit or sludge, re-grease the gears and bearings, then reassemble. As long as the air supply remains dry and free of contamination, these drills can run for decades with just basic care.

For repairs, the simple construction makes diagnosis and parts replacement very straightforward. Most components are individually replaceable rather than dealing with sealed cases and disposable subassemblies found in many electric tools. This maximizes the working life of the tool while minimizing downtime and operating costs.

Infinite Runtime

Unlike electric drills, which can experience fluctuations in torque due to voltage drops or battery drain, pneumatic drills maintain a steady stream of power throughout their operation. This unwavering torque output translates into smoother drilling, reduced kickback, and an overall more controlled experience for the user.

Moreover, the absence of an internal combustion engine or electric motor eliminates the risk of overheating, a common issue plaguing many power tools after extended use. Air drills, on the other hand, can operate continuously without the need for cool-down periods, ensuring uninterrupted productivity on even the most demanding jobsites.

They can run indefinitely without stopping as long as the air supply remains connected and unobstructed. Electric tools need to be unplugged and batteries swapped regularly which breaks the workflow. With an air drill, you just keep on drilling.

Air compressors provide a steady supply of compressed air that can power multiple tools on a continuous basis. Large job sites or factories will have banks of compressed air receivers and distribution piping so tools can be used freely without dragging hoses. Even portable compressors can provide hours of uninterrupted runtime depending on their tank capacity.

In applications like automotive repair shops, manufacturing lines or industrial facilities, having tools that can operate 24/7 without stopping is absolutely useful for efficiency. It's one of the key reasons pneumatic tools remain so ubiquitous in these settings.

Designed for professional use, the AEROPRO AP17107 reversible pneumatic drill is built tough to withstand years of heavy use. High precision chuck. Bakelite rotor blade. P6 industrial bearing,long working life. Composite with glass fiber body, light weight and not easy to be deformed in low or high temperature. Rotor have be heat treated by Ipsen which import from Germany.

Composite housing, light weight helps avoid fatigue during prolonged use. Variable speed throttle for easy starts. Precision machined gearing ensures maximum power transfer and durability. Rear exhaust directs air away from work piece. Variable-speed trigger for precise speed control. One hand push button forward/reverse controls.

Ideal for home improvement projects, body work installation and repair, farm implement assembly and repair, construction, metal or wood fabrication, general equipment, and auto repair and maintenance.

Model No:AP17107

Free Speed:700Rpm

Air Inlet (Npt):1/4"

Air Hose(Id):3/8"

Avg.Air Consumption:4cfm(114L/min)

Sug.Air Comp:2Hp

Net Weight:1.4kg

Overall Length:195mm

AEROPRO has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

AEROPRO seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Sales@Aeroprotools.Com